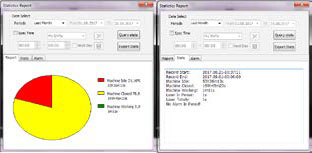

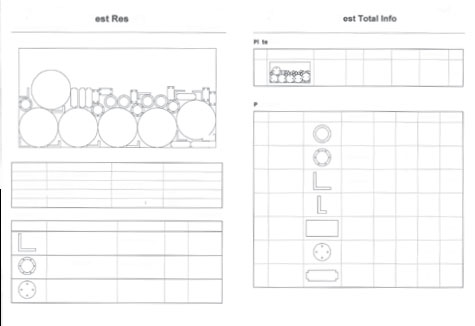

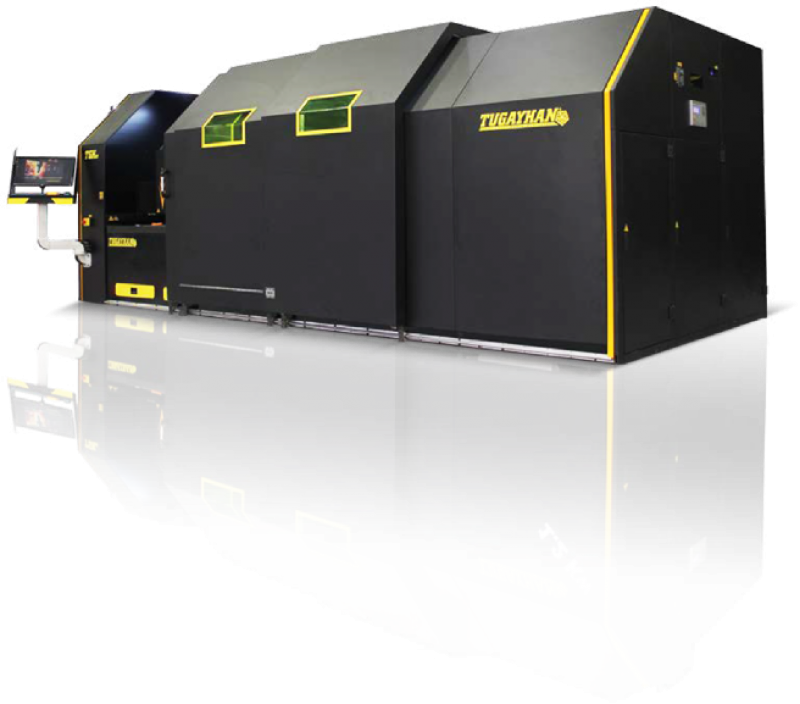

Software specially designed for fiber laser

Automatic gas pressure adjustment on software

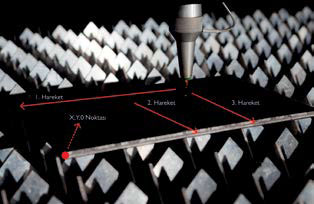

High speed precise servo motors

High resistance planet reducers

High resistance linear skids

High speed precise trolleys

Ground and hardened helix racks

Ground rigid body with source voltage taken

Special cutting table with easy sheet loading feature

Three separate gas inlets for air

Easy-to-adjust cutting head

Laser protective glass covered cabin

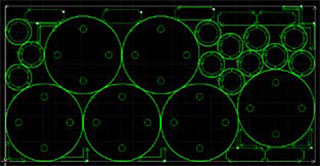

Very precise cutting capability

TGH2060 Model's working area is 2000x7000 mm single table.

With this model you can cut all 1250x2500,1500x3000,2000x4000 or 2000x6000mm sheets which are frequently used in the market.

When you hold up 2 of the 4 piston doors on the front side, it activates the 1500x3000 area. While cutting in this area, you can pick up your previously cut materials in the other 1500x3000 area.

If you hold up all 4 doors, you will activate the 2000x7000mm area and cut the large sized sheets.

Industry 4.0 or 4th Industrial Revolution is the age of machines that enable the establishment of intelligent factories that can combine and manage many modern automation systems, data exchanges and production technologies.

All necessary safety measures have been taken for the operator and the environment. All necessary safety measures are available in our machines according to the Machinery Safety Regulation. The machine has two emergency stop buttons, laser safety sensors and safety sensors. It provides the highest level of protection thanks to its enclosure and its special protective glass. One special laser safety glasses are supplied with the machine.

Our starting point was to make easy-to-use and space-saving machines. For this purpose, we designed our machines as compact and functional.

Tugayhan Machine, which stands out with its investment in R&D activities, adopts the latest technologies on the world and adapts it to its machines.

Our machine is mechanically and electronically guaranteed for 2 years.

Spare parts are stored in stock in our factory in order to prevent any delay in case of any failure.

In addition, consumables such as Protective Glass, Nozzle and Lens Lens are always in stock.

Technical Service is offered by our expert Technical Team.

In case of a failure, assistance is offered in the shortest time.

There is also remote connection and phone support.

Machine usage training is given by free of charge by our expert operators for one week in our subcontracting center.